The development of coating technology and electronic components is coordinated with each other, and with the acceleration of social development, the performance requirements of electronic components are gradually increasing, and coating technology is also particularly important. In order to ensure the stability and reliability of electronic products, it is an important link to detect and screen the coating of electronic components. Common electronic component coatings include tin-silver (Sn-Ag) coating, tin-bismuth (Sn-Bi) coating, tin-copper (Sn-Cu) coating, pre-plated nickel-palladium-gold (Ni-Pd-Au) wait.

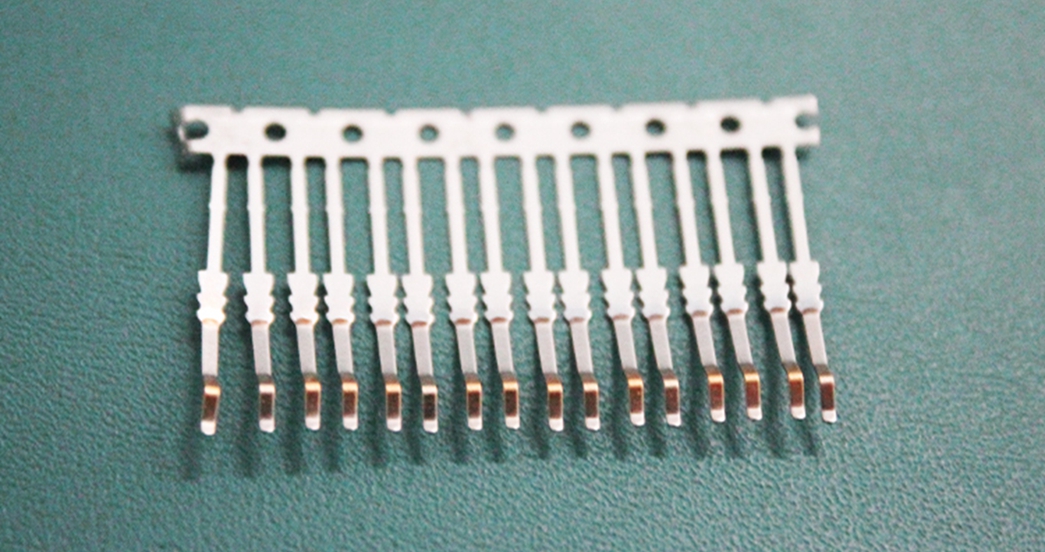

As the chip carrier of integrated circuits, the lead frame is an important basic material in the electronic information industry.

In order to ensure the chip loading/bonding performance in the packaging process, special surface treatment is required for the lead frame. Common lead frame plating elements include gold, silver, palladium, nickel, etc. In recent years, according to the needs of the industry, the coating in the lead frame has become thinner and thinner, and the high-precision X-ray fluorescence analyzer developed by LANScientific is suitable for this extremely difficult test application.It can also measure the thickness and composition of the coating at the same time, and the measurement results with high repeatability can be obtained in a short time.

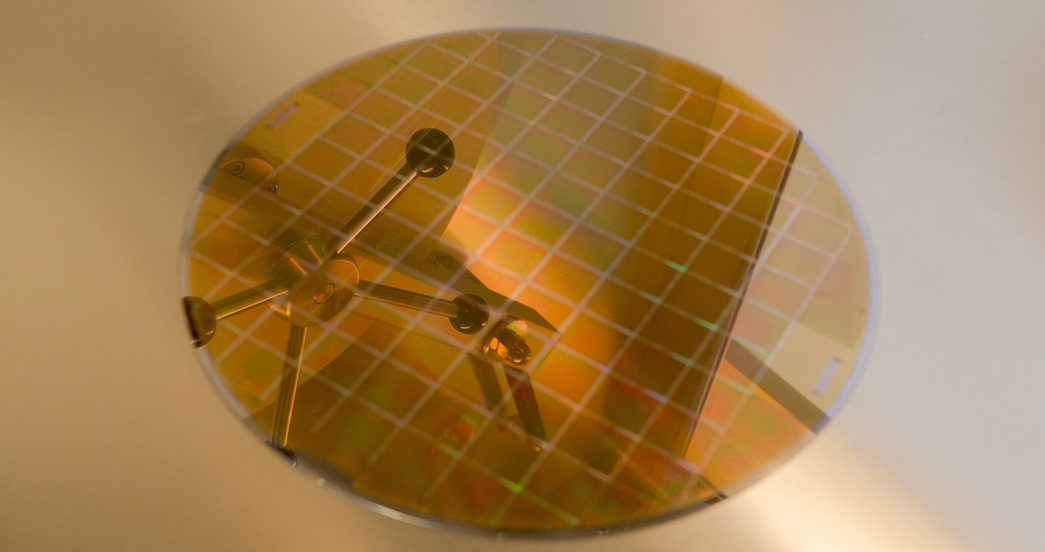

Wafer is the carrier used in the production of integrated circuits. In general, wafers refer to single crystal silicon wafers. In the production process, the wafer needs to be electroplated,which means that a layer of conductive metal is electroplated on the wafer, and the conductive metal layer will be processed later to make a conductive circuit.

As the basic material of the chip, the wafer has strict requirements on the electroplating coating, so the requirements on the process are also relatively high. The uniformity and thickness of the coating must be ensured during wafer electroplating in order to ensure the quality of the wafer.

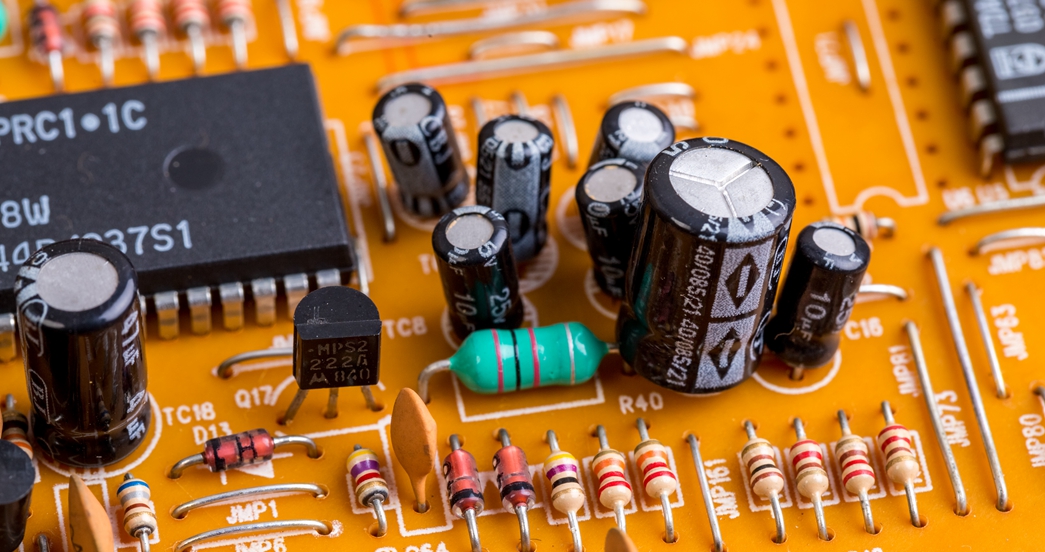

The most basic purpose of PCB surface treatment is to ensure good solderability or electrical performance. The common processes are hot air leveling, organic coating OSP, electroless nickel/immersion gold, immersion silver, immersion tin, and nickel-gold plating. INSIGHT can quickly, efficiently, non-destructively and accurately analyze the thickness and composition of PCB coatings of different shapes.

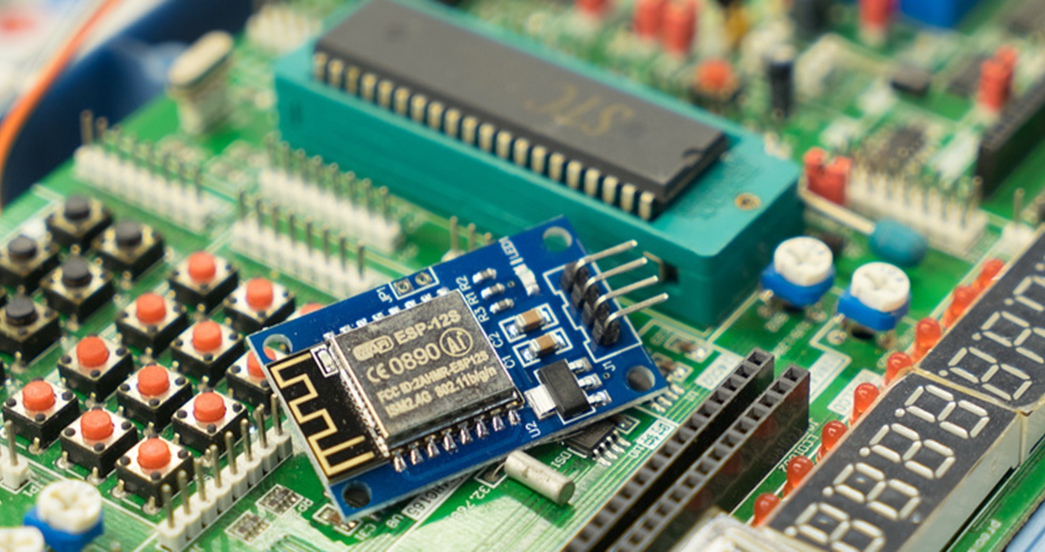

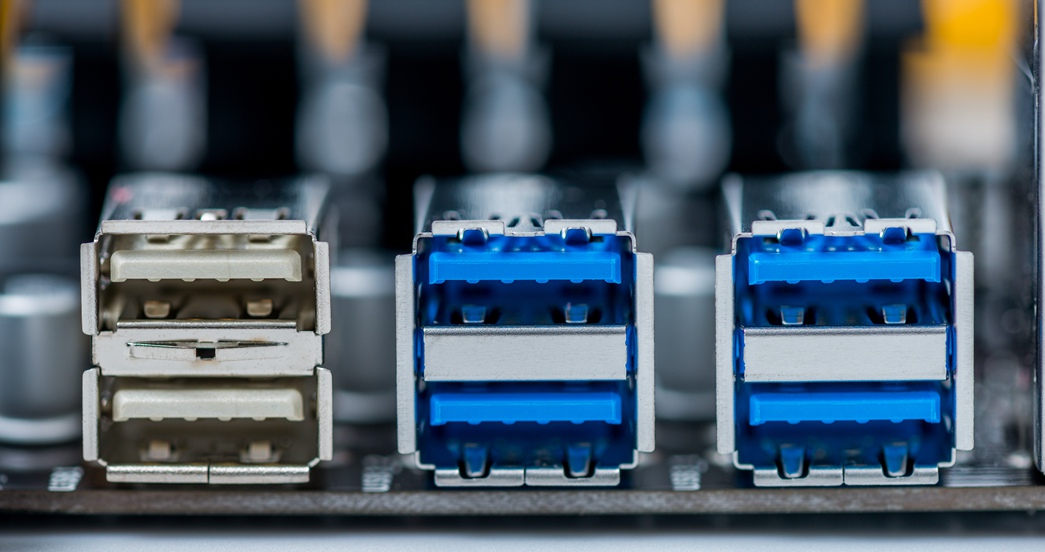

The use of protective and wear-resistant coatings for electrical contacts is increasing in the electronics and electrical industries. As the core component of the electrical connector, the contact piece can improve the corrosion resistance and wear resistance function of the contact piece through surface treatment, and can also optimize the transmission function of the contact piece to a large extent. The base material of electrical connector contacts is generally copper alloy, and the commonly used coatings are: tin plating, gold plating, silver plating, nickel plating, palladium plating, etc.

Electroless Nickel/Immersion Gold (ENIG) plating is one of the more common surface treatments used in printed circuit board manufacturing today. The International Electronics Industry Connection Consortium (IPC) published the first ENIG specification in 2002, followed by ENIG specification revision A in August 2017, which aims to help manufacturers improve the reproducibility and reliability of ENIG surface treatments sex. Revision B, launched in July 2021, focuses on the limited impact of corrosion on XRF use. LANScientific coating series analyzers can help you easily cope with ENIG measurement standards.